What is the life expectancy of the escalator handrail?

The service life of an escalator handrail is usually 5 to 10 years, but the specific service life is affected by the following factors:

I: The main factors affecting the service life of handrails

1.The frequency of use will affect the service life of the handrail

The escalators and moving walkways in these places have long daily operating hours and large passenger flow, and the service life of the handrails may be only 3-7 years.

Medium and low intensity places (office buildings, residential buildings):

The escalators and moving walkway handrails in these places are used relatively infrequently, with a service life of 7 to 10 years.

2. Different environments will affect the service life of handrails

Outdoor or semi-open-air environments (such as subway entrances and exits, outdoor escalators in shopping malls):

Ultraviolet rays and rain will accelerate the hardening and cracking of the surface of rubber handrails, and the service life may be reduced by 30%~50%.

Large temperature differences (such as below -20℃ in winter in high-latitude areas) can easily make rubber brittle and accelerate cracking.

If it is an outdoor escalator, it is recommended to use polyurethane handrails. PU material is naturally UV-resistant and has an outdoor life of more than 50% longer than rubber.

If the budget is limited, only rubber handrails can be used, and a layer of UV protection coating needs to be added to the rubber surface.

If it is an outdoor colored handrail, it is not recommended to use rubber handrails. Directly increase the budget and use colored polyurethane handrails

Indoor constant temperature is the most ideal operating environment for handrails. The rubber ages more slowly and the service life is closer to the theoretical value.

3. Different materials and processes will affect the service life of handrails

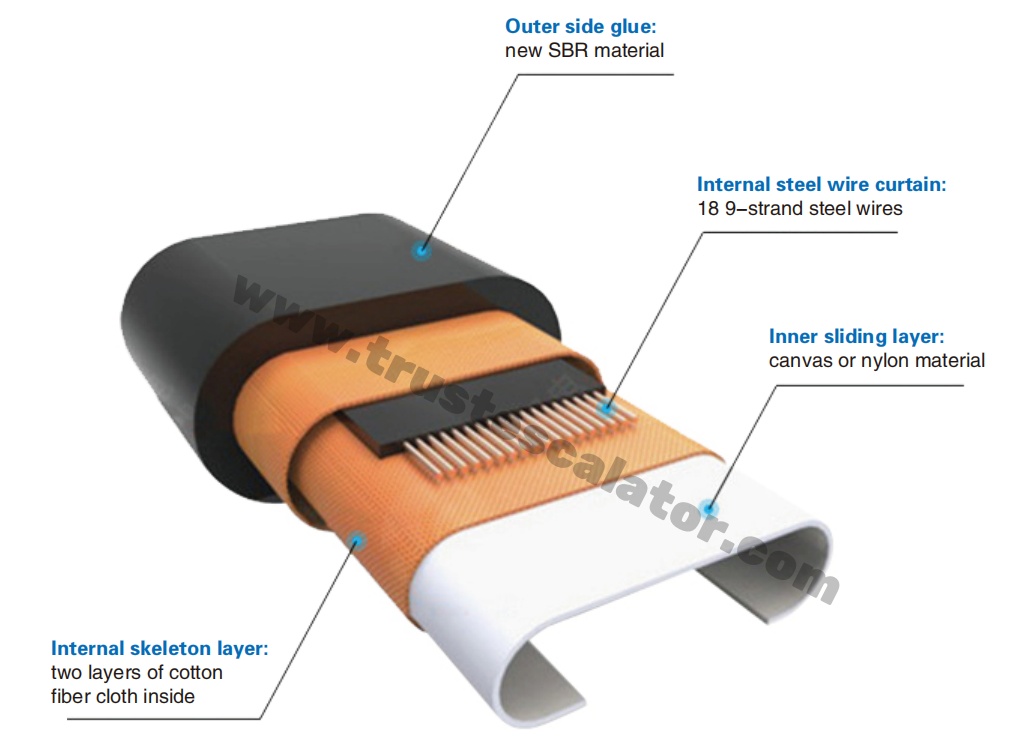

The main material of handrails is rubber or polyurethane (PU) composite materials, with steel core or fiber reinforcement layer embedded inside. The service life of handrails produced by regular manufacturers and qualified by national institutions can be guaranteed.

However, some buyers pay too much attention to the price of handrails and ignore the quality of products. In order to meet customers' demand for low prices, some manufacturers use some inferior materials to produce handrails. Handrails are prone to surface cracking, delamination, exposed steel core and other problems. The service life may be less than 3 years, which in turn leads to higher maintenance costs.

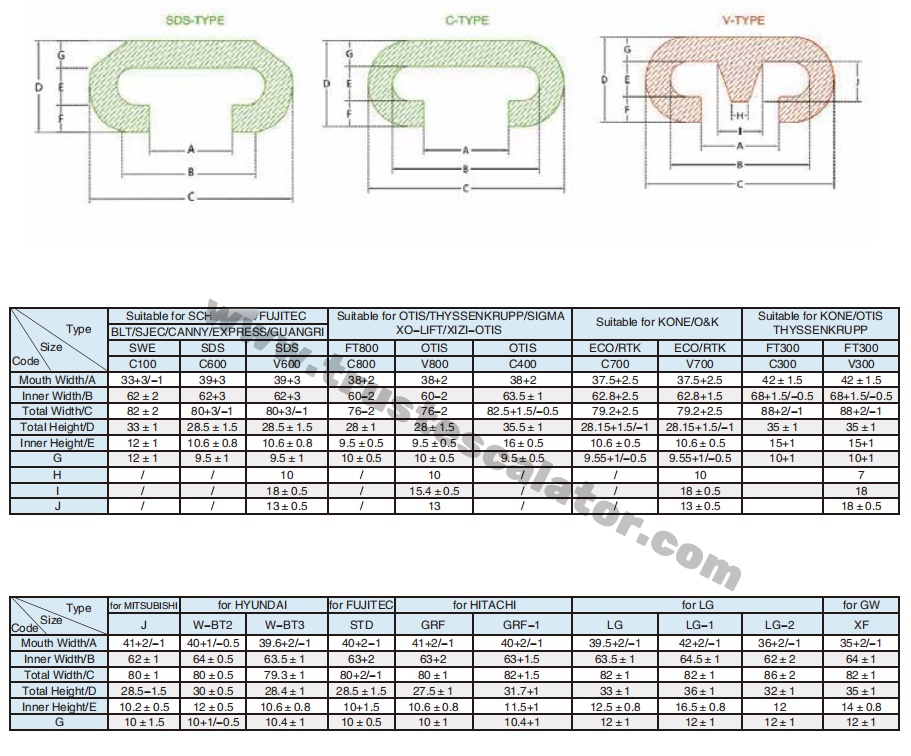

4. Differences in escalator brands:

Some Japanese brands of escalators, such as Hitachi and Mitsubishi, use linear drive, which causes greater friction and loss on the handrails.

5.The frequency of maintenance and care will also affect the service life of the handrail

Regular cleaning: Removing oil and dust from the surface of the handrail can reduce friction loss.

Lubrication system: Insufficient lubrication of the handrail guide rail will increase the running resistance of the handrail and accelerate wear.

Inspection frequency: It is recommended to check the handrail surface cracks, joint debonding, internal steel core fracture and other hidden dangers every quarter.

II. When should the handrail be replaced?

Damage on the handrail surface: deep cracks (>1mm), partial peeling or bulging.

Damage to the internal material of the handrail: broken steel core, loose fiber layer, causing the handrail to deform or slip.

Abnormal operation of the handrail: not synchronized with the step speed (the national standard requires speed deviation ≤±2%).

Ⅲ. Safety regulations and replacement recommendations for escalator handrails

National standards (such as GB 16899-2011): Handrails must be replaced when structural damage occurs, and cannot be replaced by temporary repairs such as "glue patching".

Preventive replacement: It is recommended that high-traffic places be evaluated every 5 years to avoid safety accidents caused by sudden failures.

IV. How to extend the service life of the handrail

Avoid human damage: Do not cut with sharp objects or squeeze the handrail with heavy objects (the handrail is not a conveyor belt).

Control the load: Overload operation will increase the tension of the handrail and accelerate fatigue.

Choose weather-resistant materials: UV-resistant and low-temperature-resistant polyurethane materials are preferred for outdoor places.

V: Summary

The life of handrails needs to be dynamically evaluated in combination with usage scenarios. It is recommended that escalator managers entrust maintenance companies to conduct professional inspections every two years, rather than simply relying on theoretical lifespans. If the handrails show obvious signs of aging (such as cracks, abnormal noises), escalator managers should stop using them in a timely manner and contact maintenance companies to avoid accidents such as passenger injuries.

If you have any questions about handrails, please feel free to contact us

grace@trustescalator.com Mobile:+86 150 5031 4593